Quality Engineering Department

Control, Guarantee, Calibration

Talayeh Quality Engineering

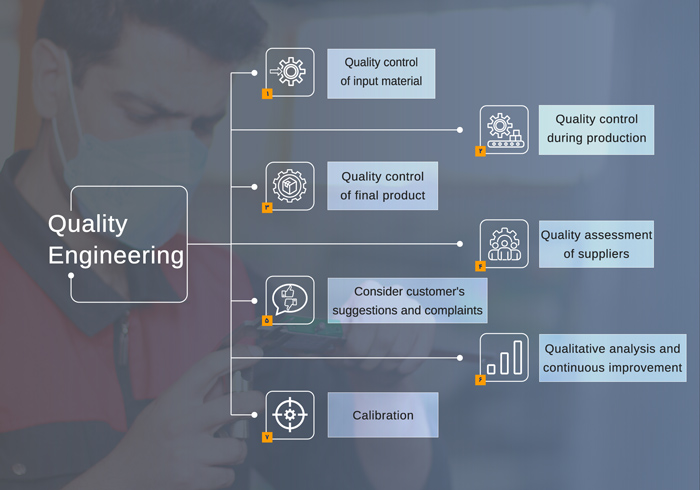

Taking into account the Talayeh’s strategy concerning manufacturing of quality products and observance of customer orientation principle, Quality Engineering Unit activities are defined in the following sections:

- Quality control of input material

- Quality control during production

- Quality control of final product

- Quality assessment of suppliers

- Consider customer’s suggestions and complaints

- Qualitative analysis and continuous improvement

- Calibration

Also, ISO 9001: 2015 and ISO 10002-2018 standards establishment is also evidenced by the above and has been effective in designing, planning and implementing all effective and efficient processes and ultimately, increasing customer satisfaction.

As stated, Engineering Quality Department controls all activities that have led to increased customer satisfaction and fulfill the above-mentioned requirements for achieving the goal, strictly.

Quality Assurance Department

This department is intended to maintain and improve the continuous process of product quality, increase customer satisfaction and continuous improvement from the past; it has succeeded in implementing quality management system and obtaining the ISO45001-2018 certificate.

Currently, in order to maintain the constant process of the quality of its products and customer satisfaction, as well as to maintain the safety and health of personnel, this company has initiated the establishment of a quality system based on ISO 9001:2015 and ISO 45001:2018 standards and obtained its certificates from TUV InterCert and MTIC.

Operating activities of quality assurance department in this company are as follows:

- Supervision of implementing all organizational processes in accordance with the quality system defined in the format of the requirements of the above standards.

- Preparation and development of all implementation methods, working instructions, forms and other documents in accordance with requirements of the above standards.

- Monitor all organizational processes.

- Control documents of Quality System.

- Conduct management review sessions and follow their approvals.

- Co-operation in preparation and formulation of organizational goals.

- Education

- Define and create the necessary tools to make continuous improvement in all aspects of the company.

- Ensure the implementation of continuous improvement in all major activities of the company and continuous promotion of quality and customer satisfaction.

- Address customer comments and complaints in accordance with ISO10002:2018 requirements.

- Internal audit of processes

Quality Control Department

The Quality Control department with use of experts and specialists, aim to ensure identification and control of the non-use and transfer of defective items and manufacture products in accordance with the requirements, monitors and measures products for verification in accordance with the “control program”, in such a way that at all stages of receiving, process and final product, items such as materials, parts and products that have the defined features and requirements are released for use in subsequent stages.

Talayeh Quality Control Department Activities

A summary of Talayeh’s Quality Control department activities is as follows:

- Quality control of input material

- Quality control of items during production

- Quality control of final product

- Quality assessment of suppliers

TALAYEH Calibration Department Activities:

This department operates in the quality engineering department by employing expert forces with the aim of identifying, maintaining, calibrating equipment and ensuring proper purchase, setup, use and maintenance of equipment and measuring tools used.